Steel Bridge

The Student Steel Bridge Competition (SSBC) is a multidisciplinary student led design competition which incorporates the aspects of design, analysis, experimental testing, time and project management, construction and fabrication methods, and economical constraints. The competition is hosted by the American Society of Civil Engineers (ASCE) and the American Institute of Steel Construction (AISC) and open to all colleges and universities with a good-standing student chapter of ASCE. The first student steel bridge competition was held in 1987 and the first national competition was held in 1992. Participation in the competition has grown significantly since that time with over two hundred colleges and universities participating in the regional level competition in 2009. About one fifth of the top regional level competitors advance to the national level competition.

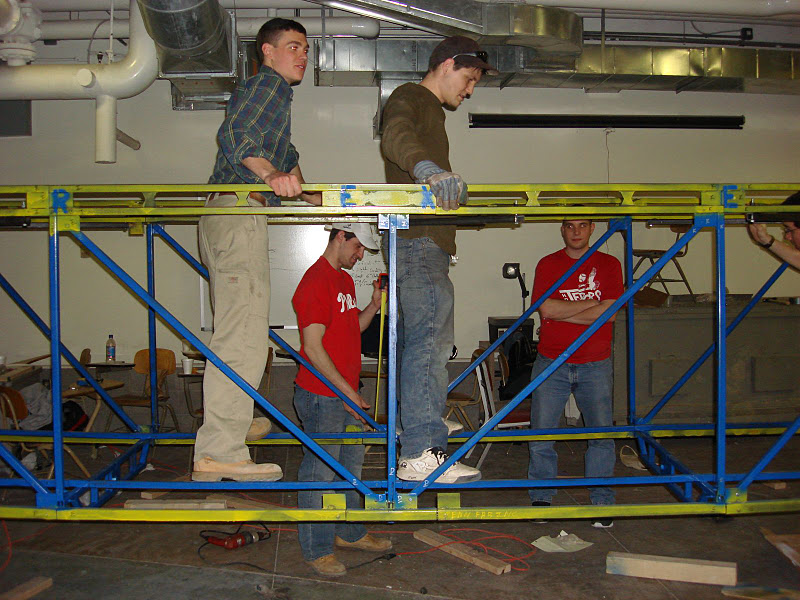

The competition involves designing and fabricating a twenty foot long steel bridge. The competition consists of three categories: Aesthetics, Construction Economy, and Structural Efficiency. Construction economy and structural efficiency are the only categories quantified in scoring. Construction economy is scored by the number of builders and how long it takes to assemble the bridge at the competition. Structural efficiency is scored by the weight and stiffness of the bridge. Twenty-five hundred pounds is loaded on the bridge while deflections are measured to determine the stiffness of the bridge. When designing, the bridge dimensions are constrained to the envelope given by the competition rules.

- 2009 Drexel Promotional Video

- Construction at Competition

- Vertical Load Testing

- Lateral Load Testing

- Clearance Requirements

The SSBC at Drexel

Drexel University uses the Student Steel Bridge Competition (SSBC) as a learning tool for teaching bridge design for undergraduate and graduate students. The competition serves as the foundation layer for the course with pertinent bridge design topics being taught as separate layers built upon the foundation layer or student competition.

Students enrolled in the fall and winter term bridge design courses will initially develop concept designs adhering to the strict guidelines by the competition rules committee. Designs are presented weekly to faculty and stakeholders for review the progress. Later in the fall term, one design will be chosen to be optimized and analyzed using structural analysis software. Once the design has matured, scale models are created along with computer generated models. Ultimately after the fall term, the final product will be a near completed design and drawing set for fabrication. The winter term will focus on fabrication methods and experimental testing of components in the design. Once the bridge has been fabricated, a full scale test is completed using gauges to measure the response of the bridge in order to calibrate the structural analysis model. The entire course also encompasses time and project management skills as well as the economical constraints typically seen in the industry.